Army Green Split Leather Military Combat Jungle Boots Hiking Boots

It's important to prepare durable footwear for soldiers combating or training. These army green combat boots are suitable for wearing in forests and fields, with super abrasion resistance. The hidden color makes it easier for soldiers to hide and protect themselves in combat and training. At the same time, these sturdy boots are also suitable for outdoor sports and mountaineering, and they can face extreme environments.

Payment: TT/LC

Min Order: 1000

Shipping Port: ANY PORT IN CHINA

Lead Time: 40-50 days

Certification: SGS testing report

ARMY GREEN GENUINE LEATHER MILITARY COMBAT JUNGLE BOOTS HIKING BOOTS

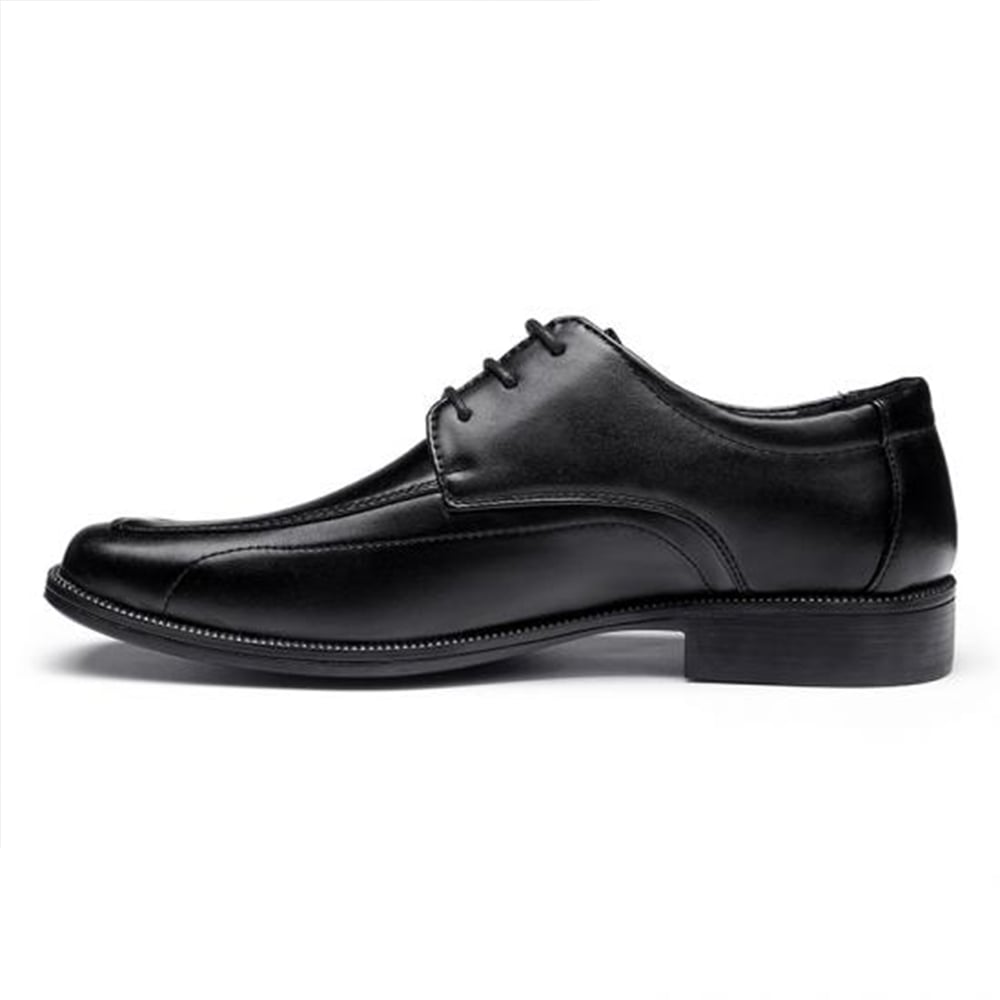

These military boots are boots designed to be worn by soldiers during combat or training. Combat Jungle boots are designed to provide a combination of grip, ankle stability, and foot protection suitable for a rugged environment. The classic black design can be matched with various military uniforms to meet the needs of combat, training, and daily wear.

SPECIFICATIONS

Product material: Split leather, 600D polyester

Size: 39-46 (EUR)

Color: Black

OEM: Acceptable

Brand: Military Boots

DETAILS SHOW

| Good-quality Split Leather | Seam on the sole | High-top Design | Durable Rubber Outsole |

|

|

|

|

Upper material: genuine leather + oxford fabric

Outsole: rubber

Color: custom

MOQ: 1000 pairs

Payment: T/T, L/C

Delivery time: 30 days

Start port: Shanghai

Certification: SGS testing report

- Occupational footwear with SRA slip resistance

- Waterproof bootie construction

- Durable full grain leather upper

- Ankle and fore-foot pads for extra protection and support

- Padded Clarino microfibre collar for comfort

- M-PACT Power PU footbed for maximum shock absorption

- Non-metallic scanner safe hardware

- EVA midsole for underfoot cushioning

- High traction outsole for maximum grip and slip resistance

- Oil resistant and slip resistant outsole

Business Type: Manufacturer

Main Products: Bulletproof Helmet, Bulletproof Plate, Bulletproof Vest, Bulletproof Backpack, Military Clothing, Tactical Gear and Outdoor Gear.

Number of Employees: 300

Year of Establishment: 1999-09-01

Management System Certification: ISO9001:2015

Primary Competitive Advantage:

♦Our factory got ISO 9001 and legit police&military certificate.

♦We have our own technology for producing bulletproof products and anti riot products.

♦We make the bulletproof products as your samples or your design full.

♦We have strong researching and developing team to solve bulletproof solutions.

♦We supply high quality products with certificated for many world famous companies.

♦Small trial orders can be accepted, free sample is available.

♦Our price is reasonable and keep top quality for every clients.

Know more about us.

Each boot in a PP bag, then 10 pairs in a big carton.

These military shoes and boots will be shipped to worldwide via the logistics method you choose or we recommend.(We have rich experience and help many customers to save a lot of freight.)

In order to better ensure the safety of your goods, we will provide professional, environmentally friendly, convenient, and efficient packaging services. You can check our service.

For more information and recommendations, please contact us.

Wholesale Custom Ankle Boot Waterproof Leather Tactical Military Combat Army Boots For Men

Product Description

- It's important to have durable footwear that protects you while following any uniform regulations.

- Each boot comes with a thick vulcanized rubber cleated Panama outsole for enhanced grip while you are on the move.

- Top-quality genuine leather achieves a good quality standard, which is more durable, comfortable, breathable.

- With optional waterproof, oil-resistant, fire-resistant, stab-proof function.

What are the production techniques of military boots?

Production Techniques

There are many conditions that are required to make a good quality military boot, from the initial design to the final molding, and the steps involved are complex and detailed. The selection of the face material, the design of the sole pattern, and the research of the molding process... Each step requires strict control and rigorous operation. Only by doing every step carefully, we can make boots like art.

A crucial step in the shoes making process is molding. It refers to the technique and method of assembling the shoe parts such as the upper and the sole to become a shoe product. The Chinese shoe-making process has been using the hand-stitching process for a long period of time. Since the 20th century, advanced technology and special equipment have been introduced from abroad, and the shoe-making process has developed rapidly. The forming process of military boots has been selected and finalized: gluing, false seams, Goodyear, mold pressing and so on. We will introduce these several processes in detail:

Cement

Also known as the cold-adhesive process, it is a process that uses an adhesive to join the upper, the insole, and the outsole together. Due to the different materials of the upper and the sole bonding surface, the type and nature of the adhesive used are different, such as neoprene adhesive, polyurethane adhesive, SBS adhesive and the like.

Goodyear Process

The military boots with Goodyear bottom are comfortable and durable, and the large bottom of the seam has many advantages. It can adapt to the thermal expansion and contraction of the upper and the sole in the environment with large temperature change. It is more suitable for the foot type, and the folding pressure is not easy to break.

Mold Pressing

It is a process for bonding the outsole and the upper together by using the rubber outsole to produce the rubber flow and the clamping pressure generated during the vulcanization process of the mold. The outsole and the upper are adhesively bonded under the high temperature and high pressure of the rubber, so the molded shoe process has the characteristics that the bottom is firmly bonded and is not easy to be opened, wear-resistant and resistant to bending.

More Militray Shoes & Boots

Dislike this one? Don't worry. We have other styles. We accept custom orders.